Kawasaki

Home

>

Case Studies

>

Kawasaki

KAWASAKI

Avercast systems allowed us to grow past our current levels and into the future as we expand.

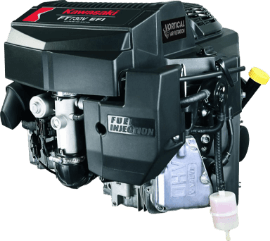

Kawasaki Heavy Industries was founded in 1896. More than one hundred years later, they process in excess of a trillion dollars in revenue each year. At a division in Grand Rapids, MI, Paul Feorene is responsible for a piece of this trillion dollar operation. Their section of the company produces general purpose engines with a focus on the commercial lawnmower market. With a current market share of about 60% in the commercial lawnmower market, there are over 7,500 independent engine dealers that Kawasaki Engines is responsible for supplying.

Kawasaki Engines currently has four different UPS managed warehouses across the U.S. in Hebron, KY, Dallas, TX, Jacksonville, FL, and Reno, NV. The combined square footage of these facilities is over 130,000. As the senior manager of logistics & parts operations, Paul and his team are responsible for forecasting and planning for nearly 13,000 SKU’s at these different facilities.

Paul himself said, “We needed… a software company that was going to be with us for more than two or three years and Avercast showed that they had the development personnel and the personality of the company to grow with us. It has allowed us to surpass the typical day to day analytical work that people in my coordinating group handle and allow us to start looking at other possibilities.”

If that sounds like a daunting task, it is. So imagine prior to 2010 when Paul and his team relied on spreadsheets to do their forecasting. Each year, the Japanese headquarters of Kawasaki would send Paul a forecast that was static, and unable to adjust for current, real-time events. In 2010, Kawasaki switched to its first remotely hosted third party planning and forecasting application.

This software helped Paul and his team see the benefits of having more accurate forecasting. However, as time went on, they outgrew the software and needed something more powerful. That’s when they found Avercast. In March 2016, Kawasaki Engines switched to Avercast and have seen the benefit ever since.

More than just freeing up time for Paul’s team to look at other issues, Avercast has freed up millions of dollars in inventory and allowed them to create new employment. Looking forward to the future, Paul and his team at Kawasaki Engines trust Avercast to continue growing with them. In Paul’s own words, “We found that the Avercast system was something that was going to allow us to grow past our current levels and into the future as we continue to expand.”